The Evolution of Mattress Packaging Machines in the Industry

In the dynamic and innovative world of mattress manufacturing, the packaging process plays a crucial role in ensuring that products reach customers safely and efficiently. Over the years, the evolution of mattress packaging machines has significantly influenced the industry, driving improvements in speed, efficiency, and sustainability. This article explores the evolution of mattress packaging machines and their impact on the industry.

The Early Days of Mattress Packaging

In the early days of mattress manufacturing, packaging mattresses was a labor-intensive process. Mattresses were typically wrapped in plastic and then manually compressed and rolled before being sealed in a cardboard box. This process was time-consuming and often resulted in bulky packages that were costly to transport and store.

The Introduction of Compression Packaging

One of the key advancements in mattress packaging came with the introduction of compression packaging. Compression packaging machines use hydraulic pressure to compress the mattress into a smaller, more manageable size. This not only reduces the overall volume of the mattress but also makes it easier to transport and store.

Compression packaging revolutionized the mattress industry by reducing shipping costs and allowing mattresses to be shipped directly to consumers' doorsteps. This innovation opened up new possibilities for online mattress retailers, who could now offer convenient, affordable shipping options to customers nationwide.

The Rise of Automated Packaging Machines

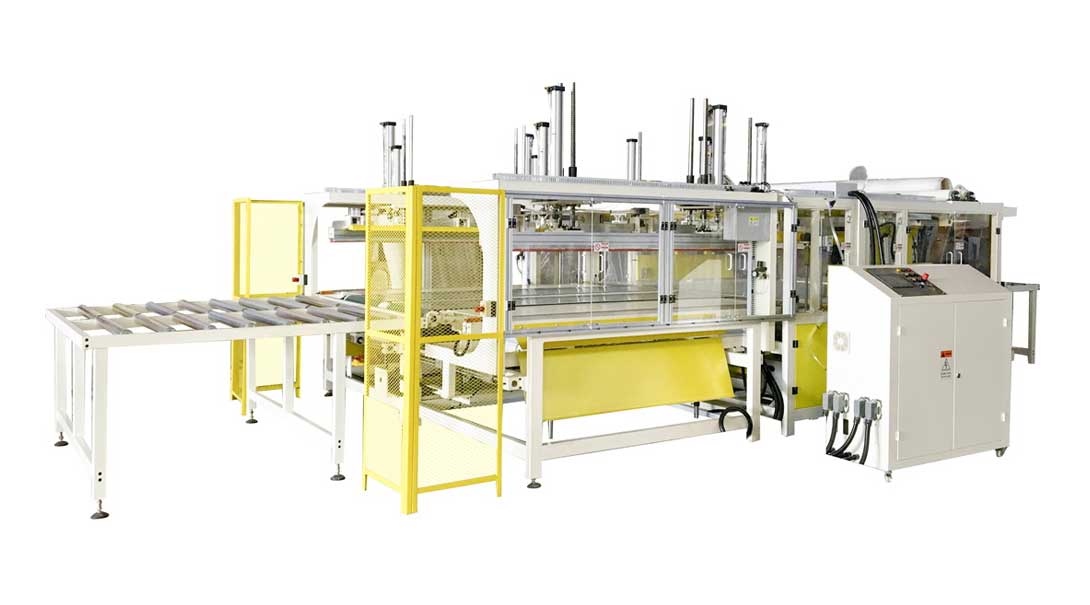

As demand for compressed mattresses grew, manufacturers began to invest in automated packaging machines. These machines are capable of compressing, rolling, and packaging mattresses in a fraction of the time it takes to do so manually. They are also more precise, ensuring that each mattress is compressed to the correct size and shape.

Automated packaging machines have significantly increased the efficiency of mattress packaging operations, allowing manufacturers to produce more mattresses in less time. This has helped to meet the growing demand for mattresses while reducing labor costs and improving overall productivity.

Advancements in Sustainability

In recent years, there has been a growing emphasis on sustainability in the mattress industry. Manufacturers are increasingly looking for ways to reduce waste and minimize their environmental impact. This has led to advancements in packaging materials and techniques that are more eco-friendly.

One example of this is the use of recycled materials in mattress packaging. Many manufacturers now use recycled cardboard boxes and plastic wrap, reducing the need for new materials and minimizing waste. Additionally, some companies have developed biodegradable packaging materials that break down naturally over time, further reducing their environmental footprint.

Future Trends in Mattress Packaging

Looking ahead, the future of mattress packaging is likely to be shaped by further advancements in automation and sustainability. As technology continues to improve, we can expect to see even more efficient and environmentally friendly packaging solutions.

One emerging trend is the use of robotic packaging machines. These machines are capable of performing complex packaging tasks with a high degree of precision, further reducing the need for manual labor. Robotic packaging machines also have the potential to increase the speed and efficiency of packaging operations, allowing manufacturers to meet growing demand more effectively.

Another trend is the use of sustainable packaging materials, such as biodegradable plastics and cardboard. As consumers become more environmentally conscious, there is a growing demand for mattresses that are packaged in eco-friendly materials. Manufacturers are responding to this demand by developing new packaging solutions that are both sustainable and effective.

Conclusion

The evolution of mattress packaging machines has had a profound impact on the industry, driving improvements in efficiency, sustainability, and cost-effectiveness. From the early days of manual packaging to the automated, eco-friendly solutions of today, packaging machines have played a crucial role in shaping the way mattresses are manufactured, shipped, and delivered to customers. As technology continues to advance, we can expect to see even more innovative packaging solutions that further enhance the mattress industry.